A COMMISSION WITH A MISSION

PUSHING THE BOUNDARIES FOR BESPOKE WATCHES

“For me, the V2+ RED CC represents everything we believe in. It’s the belief that a passionate team made up of the very best in the watchmaking industry and a visionary patron are capable of creating when they believe in the north star of the brand; the vision of creating the world’s most personal watches, which reminds us of how precious time is.”

Mark Schwarz, Founder VAULT

FIRST CARBON-CERAMIC COMPOSITE CASE

AN EXTREME COMPOSITE FOR AN EXTREME COMMISSION

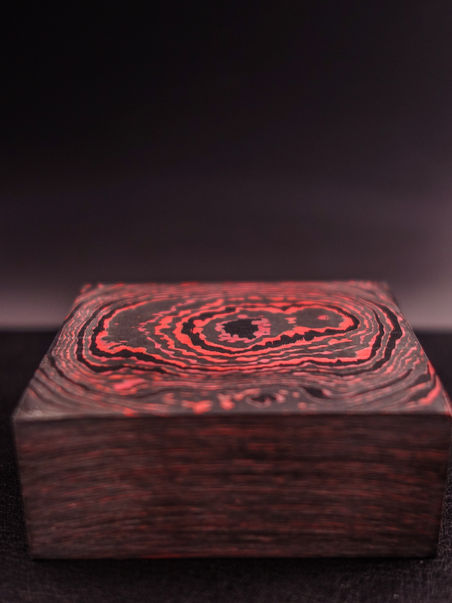

What started with the industry’s first carbon-titanium composite cased watch earlier this year has led to our latest creation—the V2+ RED CC. Once again, we have teamed up with Fatcarbon to explore the limits of composites and create a visually striking and very light material.

As far as we know the V2+ RED CC is the world’s first watch featuring a carbon-ceramic composite case.

COMPOSITE BLOCK NR. 21

THE CHALLENGING ROAD TO SUCCESS

We knew from the start that our vision for this new composite was extremely ambitious and our gut feeling proved to be right. As our case is curved in both directions, we wanted to create a composite with layers that mimicked the curvature of the case. Our partner Fatcarbon had not only to rethink his composite manufacturing process but also produce special tooling to create the desired composite. Weeks of hand-laminating layer by layer of carbon and ceramic and numerous iterations later, composite block 21 was created, which became the case for the final watch.

40+ HOURS

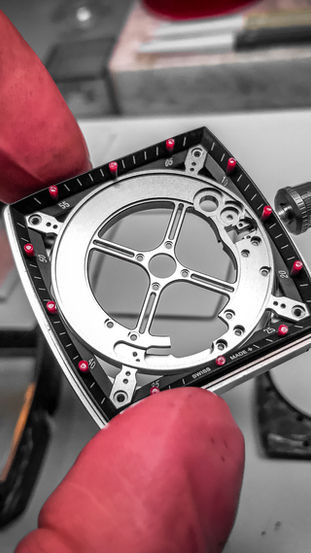

CNC MILLING ONE CASE

Our partners at RGB X-Tech, who managed to manufacture the extreme carbon-titanium composite used for the V1+ Cti, were tasked once again to machine the case for the V2+ RED CC. It took three attempts and over 120 hours of CNC milling to create the final case. As René Gschwend, CEO of RGB X-Tech, stated, this was by far the most challenging project he has ever worked on.

NEXT LEVEL FINISHING

TIME-INTENSE HAND FINISHING

We are constantly striving to up the ante to push us to the next level in creating true masterpieces. Case in point is the finishing quality of our latest creation for which we teamed up with Bernhard Zwinz. The V2+ RED CC features a hand-angled polished and brushed minute hand, a hand-grained hour disc, hand-finished gear train, hand-finished bridges and rotor. Virtually every visible component is meticulously finished and given the treatment it deserves.

EXTENSIVE TESTING

PIONERING NEW SKILLS

Using a composite never before used in the watch industry was equally exciting as it was challenging. Thanks to our visionary patron and our incredible team, we once again managed to pull off a world`s first in the industry by creating a carbon-ceramic composite case. We invested a lot of time in extensive testing to make this daring vision become a reality, in doing so pushing the boundaries once again.

122 DAYS

FROM INCEPTION TO COMPLETION

Passion is an incredible source of power and perseverance, both of which are needed to pull off this project and by doing so create a new reference for the brand. The challenges were many and the days long, but the result has been worth every second of precious time dedicated to creating this commission.

tECHNICAL sPECIFICATIONS

MOVEMENT

+ V01+ automatic movement (exclusively made for VAULT by Uhrteil)

+ Inertia regulated balance wheel

+ Power reserve: ca. 55 hours

+ Frequency: 21`600 vph

+ Rhodium-plated brushed and pearl-blasted skeleton rotor (made by Marc Jenni)

+ Pearl-blasted rhodium-plated centre plate

+ Black rhodium-plated brushed and bevelled bridges

+ Lasercut and hand-finished grade two titanium engraving bridges

case

+ 5-part case

+ Unique VAULT V2+ RED CC carbon-ceramic composite

+ 39mm Width

+ 46.7mm Length

+ 15mm Thickness

+ Sapphire crystal with a double anti-reflective coating ARunic®

+ Open case back sapphire crystal with a double anti-reflective coating ARunic®

+ Grade five titanium screws with signature VAULT screw head profile

+ Grade five titanium 2-part crown

+ Pearl blasted grade five titanium mono-cage II